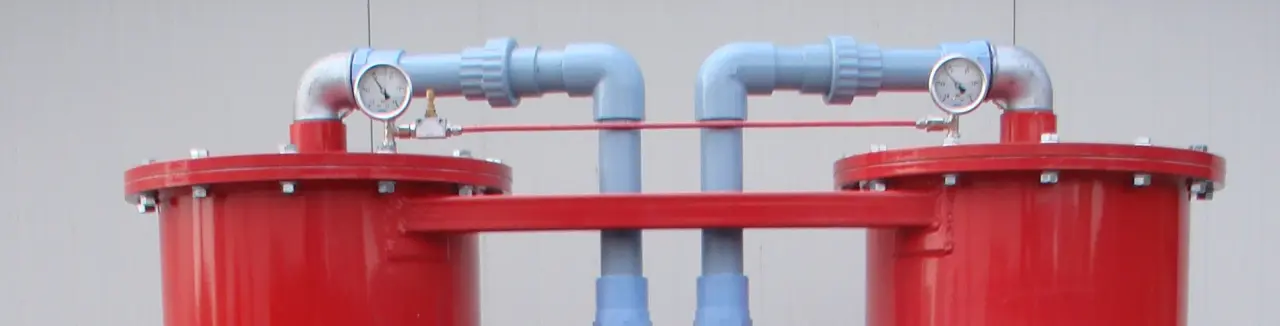

STOREX VSA N2 GENERATORS

Nitrogen is used for an accelerated pull down of the oxygen content at the start of CA storage. Breathing is slowed down faster and that is good for preserving the hardness of apples. It is also useful to lower the oxygen content with nitrogen after the cells have been opened in the meantime.

If the oxygen content rises during storage due to (unwanted) leakage, a small amount of high-purity nitrogen is injected into the cell to prevent leakage.

Nitrogen is therefore important to keep the oxygen content low.